Wood protection and surface treatment

Tehomet’s wooden poles are designed to withstand harsh and varying conditions. We have supplied wooden poles to more than 30 countries, and have tested them in extreme conditions. Seasonal differences in temperature may exceed 80 degrees Celsius in cold Nordic countries, and UV radiation can be very intense in the Middle East.

The long service life of wooden poles demands high-quality timber and proven surface treatments. We use a surface treatment system that was developed by Teknos in Finland.

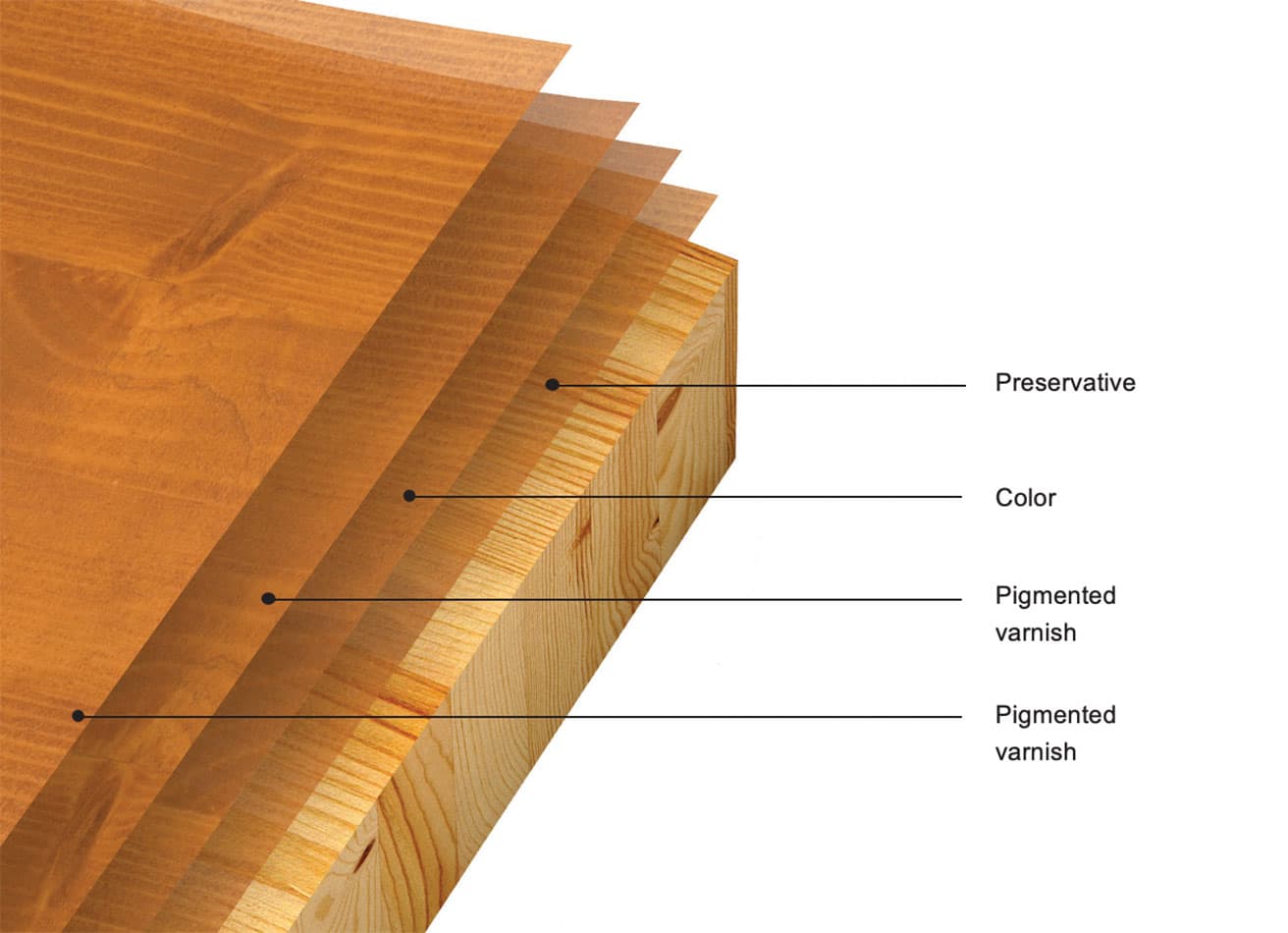

Our wooden poles are coated in several protective layers, each with its own job to do. We have chosen our surface treatment methods in order to achieve two important goals: environmental friendliness and the best protection for a wooden product throughout its entire lifecycle. Protective agents that are both water-soluble and environmentally friendly help our wooden poles to stay beautiful for a long time.

A drying chamber is used between coats to achieve a uniform result.

Surface treatments are tested in accordance with the EN 927-5 and EN 927-6 standards. Steel components are powder coated and hot-dip galvanized in accordance with the EN ISO 1461 standard.

Wood will expand and contract to some extent in response to changes of season and variations in humidity. That’s why we use flexible surface finishes that can adapt to these natural changes.

The first layer protects the wood from mould, rot and blue stain. The second layer gives the wooden pole a beautiful translucent hue in accordance with the customer’s wishes. The following coats of tinted varnish will provide improved protection from both UV radiation and variations in weather and humidity for many years to come.

An optional additional coat is also available for coastal regions or areas subject to intense UV radiation.

Standard colors for wood surfaces

Caramel

Cinnamon

Cocoa

Nutmeg

Saffron

Onyx

Slate

Topaz

Vanilla

Standard colors for metal parts of wooden poles